Efficiency is crucial in wire harness assembly, yet the current industry standard often falls short, burdening wire harness manufacturers with printed schematics, disparate information sources, and cumbersome wooden harness boards. This process is archaic and has not been innovated since 1920! This article explores how HarnessWorks revolutionizes wire harness assembly, bringing this process into the present, offering a streamlined solution that enhances productivity and reduces costs.

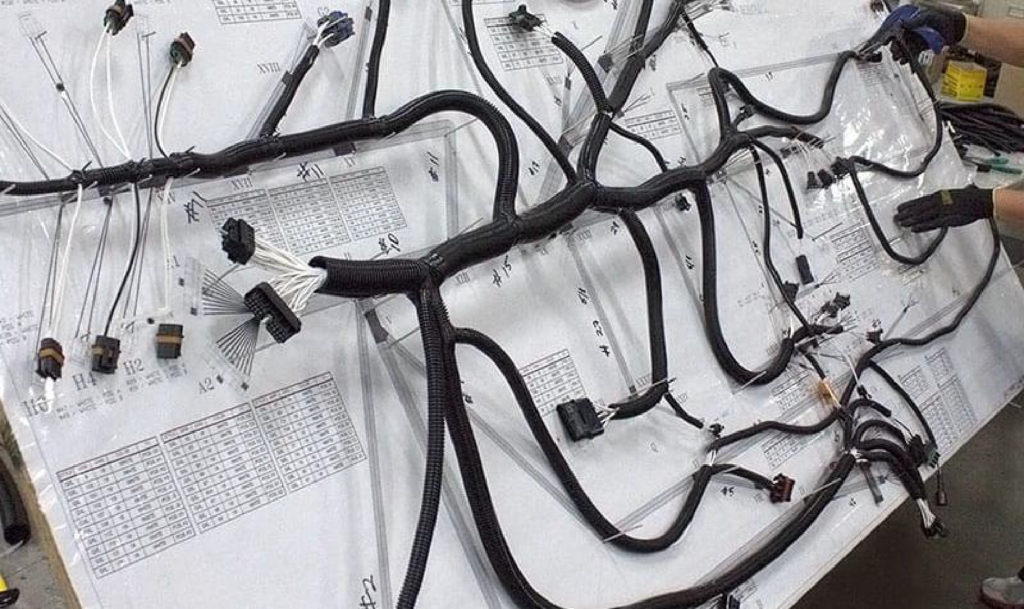

Printed Schematics

Traditionally, wire harness assembly relies on printed schematics, which are static and prone to errors. Technicians must decipher complex diagrams, leading to inefficiencies and potential rework. The printed schematics are often outdated compared to engineering drawings as there is no streamlined process to push updates to the assembly floor.

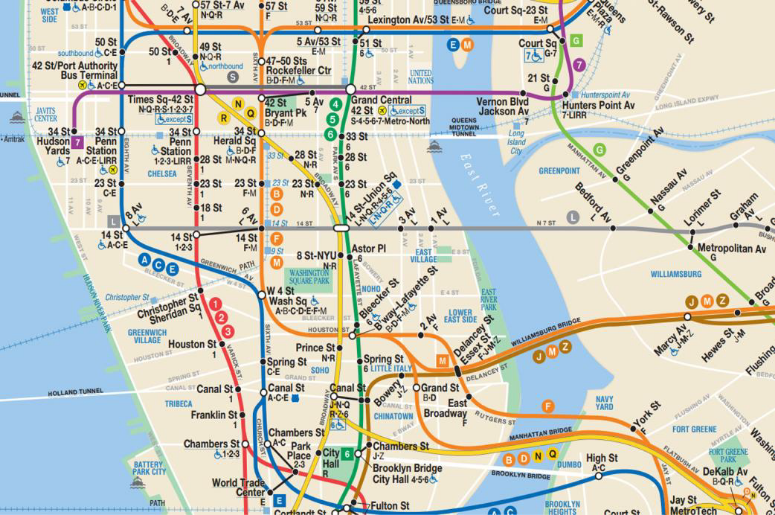

Separate Information Sources

Critical information necessary for assembly, such as manuals and specifications, is often scattered across various sources. This disjointed approach complicates the process and prolongs the learning curve for technicians. Technicans often invest more time trying to track down information than assembling a wire harness.

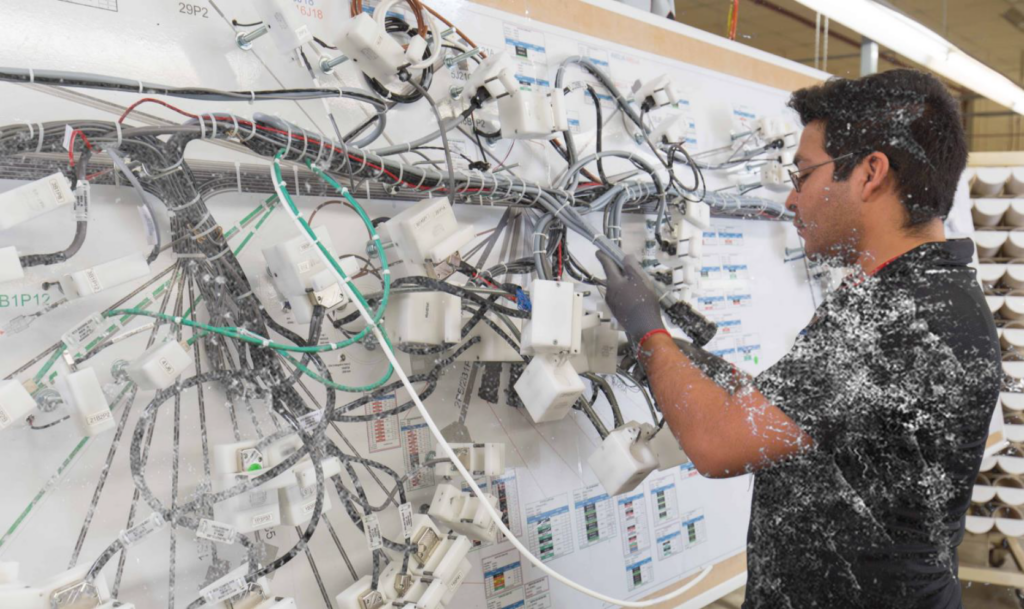

Storage of Wooden Harness Boards

The traditional practice within the industry involves the use of wooden harness boards for assembly tasks. However, this method comes with several drawbacks. Firstly, these boards consume a significant amount of space, resulting in storage difficulties and increased costs. Moreover, their inflexibility requires manual updates, contributing to the overall operational overhead. Furthermore, there’s the missed opportunity of utilizing the floor space for producing additional wire harnesses instead of storing wooden boards.

High Learning Curve

Mastering wire harness assembly entails navigating through a maze of internal systems to access relevant information. The steep learning curve consumes time and resources, hindering overall efficiency.

Costly Turn-Over

High turnover rates among technicians compound the challenges associated with wire harness assembly. Training new personnel becomes a constant endeavor, draining resources and disrupting workflow.

HarnessWorks offers a paradigm shift in wire harness assembly by integrating hardware and software to deliver real-time instructions directly onto the harness board. This innovative solution simplifies the assembly process and empowers technicians with on-demand access to critical information.

Reduce Rework

HarnessWorks minimizes errors and rework by providing clear and dynamic instructions, eliminating the guesswork associated with traditional printed schematics.

Increase Speed

By presenting precise instructions in real-time, HarnessWorks accelerates assembly speed, optimizing workflow and enhancing overall productivity.

FAST

SLOW

Reduce Cost

HarnessWorks eliminates the need for costly wooden harness boards and reduces storage expenses. Moreover, by streamlining the assembly process and minimizing errors, HarnessWorks contributes to long-term cost savings.

PRINTING

STORAGE

Data-Driven Insights

Managers gain valuable insights into production activities through HarnessWorks’ real-time dashboards and trend analysis. This data-driven approach enables informed decision-making and proactive optimization of assembly processes.

ANSWER QUESTIONS LIKE

User

In conclusion, HarnessWorks represents a revolutionary solution that transforms wire harness assembly into a streamlined and efficient process. By simplifying instructions, reducing errors, and enhancing control, HarnessWorks sets a new standard for productivity and cost-effectiveness in the industry.

1. How does HarnessWorks differ from traditional wire harness assembly methods?

HarnessWorks integrates hardware and software to deliver real-time instructions directly onto the harness board, streamlining the assembly process and minimizing errors.

2. What are the key benefits of using HarnessWorks?

HarnessWorks reduces rework, increases assembly speed, cuts costs associated with traditional methods, and provides managers with valuable data-driven insights.

3. Can HarnessWorks be customized to specific assembly requirements?

Yes, HarnessWorks is highly customizable, allowing businesses to tailor instructions and workflows to their unique needs and preferences.

4. How easy is it for technicians to adapt to using HarnessWorks?

HarnessWorks is designed with the end-user in mind, featuring intuitive interfaces and clear instructions, making it easy for technicians to adapt and utilize effectively.