Wire harness boards are essential tools used in various industries for organizing and assembling electrical wiring systems. These boards provide a stable platform for laying out and securing wires, ensuring efficient production processes. Among the materials used in manufacturing wire harness boards, powder coated steel stands out for its durability, reliability, and versatility.

Enhanced Durability

Powder coated steel wire harness boards are known for their robustness and longevity. The powder coating adds an extra layer of protection, making them resistant to scratches, abrasions, and impacts.

Corrosion Resistance

Unlike traditional steel, which is susceptible to rust and corrosion, powder coated steel remains unaffected by environmental factors such as moisture and chemicals. This makes it ideal for use in diverse industrial settings

Aesthetic Appeal

In addition to its functional benefits, powder coated steel wire harness boards offer aesthetic advantages. The powder coating can be customized to match specific color preferences, enhancing the overall appearance of the workspace.

Wire harness boards find extensive use across various industries, including automotive manufacturing, electronics assembly, and aerospace engineering. In the automotive sector, they facilitate the efficient production of vehicle wiring harnesses, ensuring reliability and consistency in electrical systems. In electronics manufacturing, wire harness boards play a crucial role in organizing complex wiring configurations, improving efficiency and productivity. Similarly, in the aerospace industry, where precision and reliability are paramount, powder coated steel wire harness boards provide a stable platform for assembling intricate wiring systems.

Strength and Sustainability

Powder coated steel wire harness boards are renowned for their strength and stability, providing a reliable foundation for wiring operations. They can withstand heavy loads and resist deformation, ensuring consistent performance over time.

Customization Options

Manufacturers offer a range of customization options for powder coated steel wire harness boards, including size, shape, and color. This allows businesses to tailor the boards to their specific requirements, optimizing workflow and efficiency.

Environmental Friendliness

Powder coated steel is an environmentally friendly material, as the powder coating process generates minimal waste and emissions. Additionally, steel is highly recyclable, contributing to sustainable manufacturing practices.

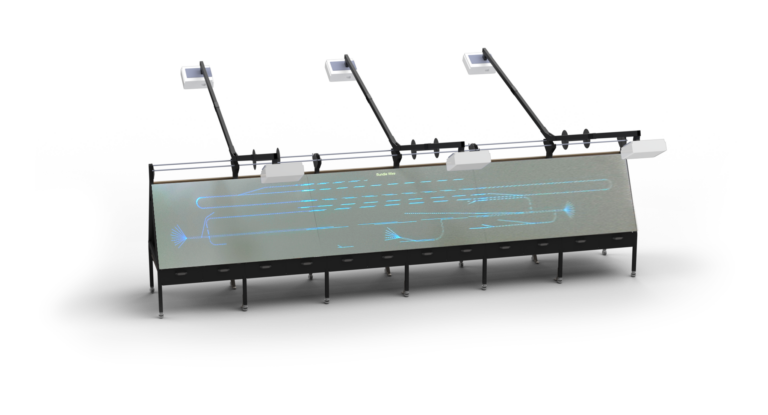

When selecting a wire harness board for your application, several factors should be considered. These include size and dimensions, material composition, and customization options. It’s essential to assess your specific requirements and choose a board that offers the features and functionality you need to optimize your production processes. Fortunately, HarnessWorks was designed to be seamlessly expandable to fit any size wiring harness.

Regular Cleaning

Keep your powder coated steel wire harness boards clean by regularly wiping them down with a mild detergent solution and water. Avoid using abrasive cleaners or solvents that could damage the powder coating.

Inspection for Damage

Periodically inspect the wire harness boards for any signs of damage, such as scratches, chips, or corrosion. Address any issues promptly to prevent further deterioration and maintain the integrity of the coating.

Proper Storage

When not in use, store the wire harness boards in a clean, dry environment away from excessive moisture and humidity. Proper storage helps prevent corrosion and prolongs the lifespan of the boards.

Initial Investment vs. Long-term Benefits

While powder coated steel wire harness boards may have a higher initial cost compared to other materials, such as plastic or aluminum, their durability and longevity offer long-term cost savings. Investing in quality boards upfront can result in reduced maintenance and replacement expenses over time.

Cost-effectiveness of Durable Materials

Despite the initial investment, the use of durable materials like powder coated steel can lead to significant cost savings in the long run. These materials require less frequent replacement and maintenance, resulting in lower overall costs for businesses.

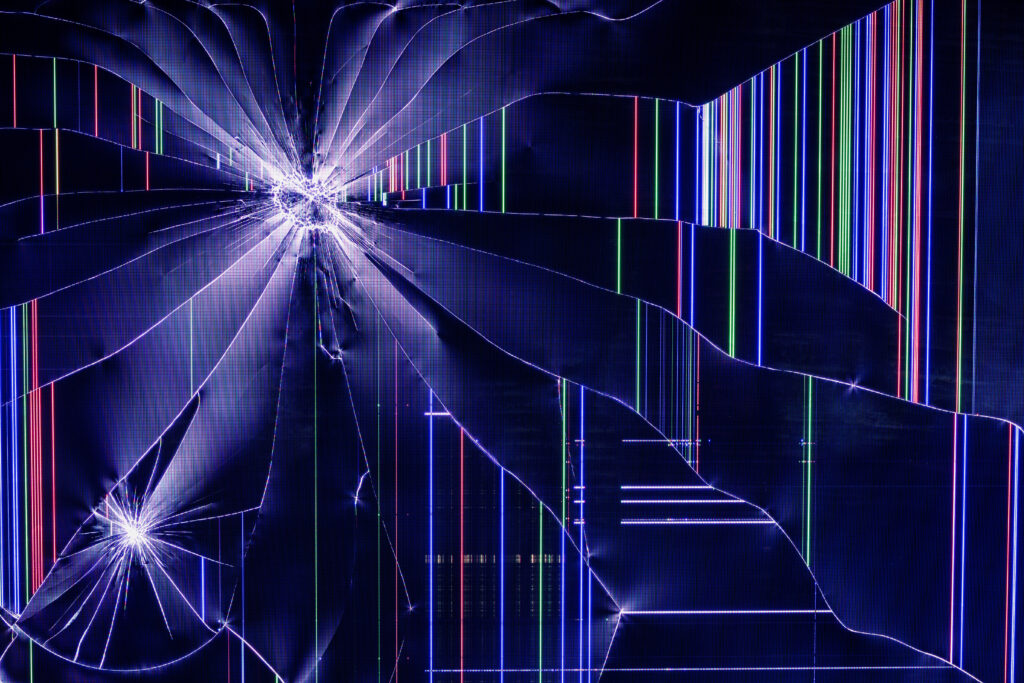

Digital Screens

Digital screens present an impractical solution. Unlike powder-coated steel, digital screens are fragile and often come with unattractive bezels. Moreover, these solutions are prone to a myriad of issues well-known in the television industry such as burn-in and backlighting problems.

Virtual/Augmented Reality Glasses

HarnessWorks has been specifically crafted to seamlessly integrate with future Augmented Reality eyewear. However, the current form factor of mainstream VR/AR headsets is not conducive to prolonged use by multiple technicians. Until smart eyewear achieves mass consumer mainstream adoption, akin to the success of the Apple Watch, VR/AR solutions remain expensive and pose health hazards. Frankly, nobody wants someone else’s sweat touching their forehead!

Automotive Manufacturing Case Study

A leading automotive manufacturer implemented powder coated steel wire harness boards in its production facility, resulting in improved efficiency and reduced downtime. The durability of the boards ensured consistent performance, leading to higher quality vehicle wiring harnesses.

Electronics Assembly Case Study

A electronics assembly company adopted powder coated steel wire harness boards to organize and streamline its wiring processes. The customizable features of the boards allowed for efficient layout planning, leading to increased productivity and cost savings.

Aerospace Application Case Study

In the aerospace sector, a manufacturer utilized powder coated steel wire harness boards to assemble complex wiring systems for aircrafts. The strength and stability of the boards met the stringent requirements of the industry, ensuring reliable performance in critical applications.

Advancements in Powder Coating Technology

Ongoing advancements in powder coating technology are expected to further enhance the durability and performance of powder coated steel wire harness boards. New formulations and application techniques may offer improved resistance to abrasion, chemicals, and UV exposure.

Integration with Industry 4.0

The integration of wire harness boards with Industry 4.0 technologies, such as automation and digitalization, is anticipated to revolutionize production processes. Smart wire harness boards equipped with sensors and connectivity capabilities could provide real-time monitoring and optimization of wiring operations.

Recyclability of Powder Coated Steel

Powder coated steel is highly recyclable, making it an environmentally sustainable choice for wire harness boards. By using recycled steel and minimizing waste in the manufacturing process, businesses can reduce their carbon footprint and contribute to a circular economy.

Reduction of Waste in Manufacturing Processes

The powder coating process generates minimal waste compared to traditional painting methods, contributing to resource efficiency and waste reduction. By adopting sustainable manufacturing practices, companies can minimize their environmental impact while producing high-quality wire harness boards.

Handling and Transportation Challenges

One challenge associated with powder coated steel wire harness boards is their weight, which can make handling and transportation more cumbersome. However, each powder coated steel wire harness board is equipt with casters to be easily rolled around on wheels.

Addressing Specific Industry Requirements

Different industries may have specific requirements for wire harnesses, such as size, material, and customization options. The HarnessWorks LightboardTM is seamlessly expandable to fit wire harnesses of any size.

Industry-specific Regulations

Various industries, including automotive, electronics, and aerospace, have specific regulations and standards governing the use of wire harness boards. Manufacturers must ensure compliance with relevant regulations, such as RoHS and REACH, to meet industry requirements and ensure product safety and quality.

Quality Standards for Wire Harness Boards

Quality standards, such as ISO 9001 and IPC/WHMA-A-620, provide guidelines for the design, manufacturing, and inspection of wire harness boards. Adhering to these standards helps ensure consistency, reliability, and performance in wire harness assembly processes.

Powder coated steel wire harness boards offer numerous benefits, including enhanced durability, corrosion resistance, and customization options, making them ideal for various industrial applications. By choosing the right wire harness boards and implementing proper maintenance practices, businesses can optimize their production processes, reduce costs, and achieve long-term success in their respective industries. With ongoing advancements in technology and a growing focus on sustainability, powder coated steel wire harness boards are poised to play a crucial role in the future of wiring assembly.